Table of Content

Try Vizitor for Free!

Published on: Mon, Aug 25, 2025

Read in 6 minutes

Introduction: The Hidden Risks in Manufacturing Visitor Management

Manufacturing facilities are some of the most dynamic and high-risk environments in any industry. Between heavy machinery, strict compliance standards, and the constant flow of contractors, suppliers, and visitors, ensuring both safety and efficiency is a huge challenge.

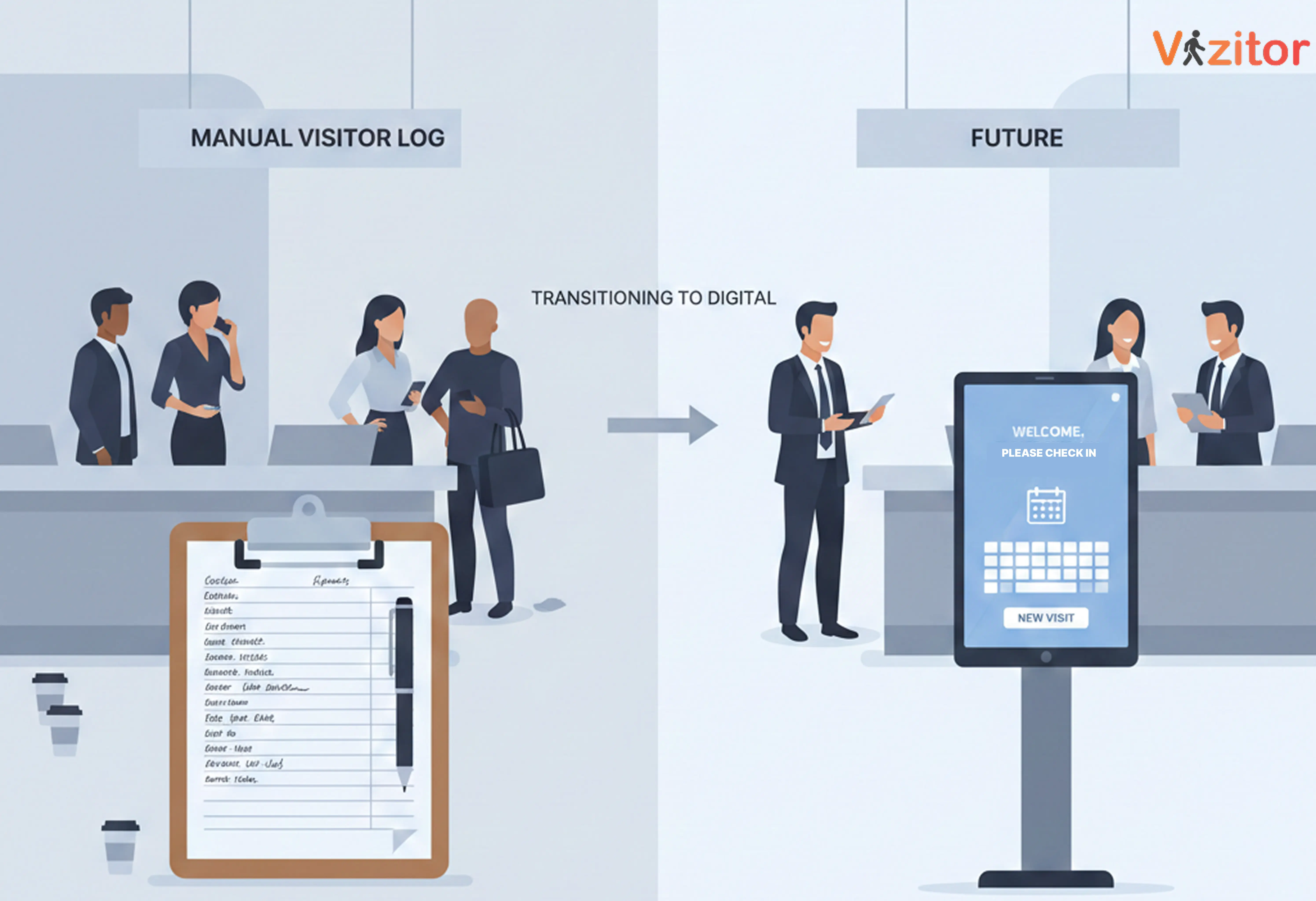

Yet, in 2025, many manufacturing units still rely on outdated visitor books or paper registers. Not only do these manual systems slow down operations, but they also expose organizations to security risks, compliance issues, and reputational damage.

This is where a Visitor Management System (VMS) steps in, a modern digital solution that helps manufacturers streamline check-ins, strengthen security, and maintain compliance with regulatory frameworks.

In this blog, we’ll explore:

- Why traditional visitor check-in systems fail in manufacturing.

- The benefits of visitor management systems for industrial environments.

- How VMS ensures compliances and industry-specific standards.

- Real-world examples of how solutions like Vizitor help manufacturers improve efficiency, safety, and trust.

The Problem with Manual Visitor Tracking in Manufacturing

A typical day in a manufacturing facility sees:

- Contractors coming in for maintenance.

- Vendors delivering raw materials.

- Customers or stakeholders visiting for plant tours.

- Government inspectors conducting audits.

Managing all this with pen-and-paper sign-in sheets creates multiple problems:

- Security Gaps - It’s nearly impossible to verify visitor identity or track unauthorized access in real time.

- Compliance Risks - Auditors require clear visitor logs. Handwritten registers are prone to errors and illegibility.

- Emergency Situations - In case of fire or evacuation, manual logs don’t provide accurate, instant reports of who is inside.

- Inefficiency - Reception staff spend unnecessary time checking in visitors instead of focusing on critical administrative work.

Simply put, manual processes no longer fit into the Industry 4.0 ecosystem where automation, AI, and IoT define productivity and safety.

What Is a Visitor Management System (VMS)?

A Visitor Management System is a digital solution that automates the check-in process for anyone entering a facility. Instead of signing paper logs, visitors can:

- Pre-register online before arrival.

- Check-in via QR code, biometric, or self-service kiosk.

- Receive a digital or printed visitor badge.

- Get their details stored securely in a cloud-based system.

For manufacturing facilities, this means a seamless and secure way to manage visitor data while keeping operations compliant and efficient.

Why Manufacturing Facilities Need a Visitor Management System

Here are the top reasons manufacturers are switching to VMS in 2025:

1. Enhanced Security & Controlled Access

Unauthorized access can cause intellectual property theft, sabotage, or accidents. With VMS:

- Visitors are verified with ID scans, OTPs, or photo captures.

- Access can be restricted to certain areas.

- Security staff receive real-time notifications about new check-ins.

This ensures only authorized individuals move through sensitive areas like production floors or R&D labs.

2. Compliance with Industry Regulations

Manufacturing is a heavily regulated sector, requiring compliance with:

- OSHA (Occupational Safety and Health Administration).

- ISO certifications for quality and safety.

- Local government audit requirements.

A digital visitor log ensures:

- Easy access to historical visitor data during audits.

- Zero errors compared to manual entries.

- Automated compliance reporting.

3. Emergency Preparedness

In emergencies like fire or chemical leaks, knowing who is inside the premises is crucial.

With VMS, facility managers can:

- Generate instant reports of all visitors on-site.

- Send mass evacuation alerts via SMS or email.

- Track safe exits in real time.

This feature alone makes VMS a life-saving investment for high-risk industrial sites.

4. Improved Efficiency & Productivity

Reception staff no longer need to manually register visitors. Instead, with kiosks or QR check-ins, the process is automated.

- Contractors check in faster, minimizing downtime.

- Suppliers can pre-register deliveries, reducing waiting times.

- Visitor data syncs instantly to the system for reporting.

This saves both time and manpower.

5. Building Trust & Professionalism

When stakeholders, auditors, or clients visit your facility, a digital check-in system creates a modern, professional first impression.

It shows your commitment to:

- Digital transformation.

- Safety and compliance.

- Operational excellence.

The ROI of Visitor Management Systems in Manufacturing

Some facility managers hesitate, assuming VMS is an extra cost. But in reality, the ROI is significant:

- Reduced risk of compliance fines.

- Lower administrative costs (no manual paperwork).

- Improved contractor productivity.

- Avoidance of security breaches that can cost millions.

In short, VMS is not just a security tool but also a business enabler.

How Vizitor Powers Manufacturing Visitor Management

Among the many VMS options, Vizitor is designed with manufacturing in mind.

Key features include:

- Touchless Check-In via QR codes and kiosks.

- Pre-registration for contractors and vendors.

- Real-time visitor logs accessible anytime.

- Emergency evacuation tools to ensure safety.

- Customizable visitor badges with photos and access levels.

- Compliance-friendly reports for audits.

By choosing Vizitor, manufacturing plants get a secure, scalable, and easy-to-implement solution that enhances both safety and efficiency.

Case Example: A Manufacturing Facility with VMS

Imagine a steel manufacturing plant that receives:

- 200+ contractor visits weekly.

- Regular safety inspections.

- International clients for tours.

With manual logs, they struggled with lost entries, delayed audits, and security lapses.

After adopting Vizitor:

- Check-in time reduced by 70%.

- Audit compliance became error-free.

- Emergency evacuations were faster and more accurate.

- Stakeholder confidence increased significantly.

The Future: AI-Powered Visitor Management in Manufacturing

Looking ahead, visitor management in manufacturing will go beyond just check-ins:

- AI-driven facial recognition for faster authentication.

- Integration with IoT sensors to monitor visitor movement in restricted zones.

- Predictive analytics for visitor flow optimization.

- Digital twin technology to simulate and manage facility access.

This means manufacturing facilities will not only be safer but also smarter.

Conclusion: A Smart Investment for Manufacturers

In the fast-paced, high-risk world of manufacturing, relying on outdated visitor logs is a gamble. A Visitor Management System offers:

- Security

- Compliance

- Efficiency

- Professionalism

For manufacturers serious about safety, compliance, and modernization, the choice is clear: it’s time to adopt a digital visitor management system.

And with Vizitor, facilities get a solution built for their specific challenges: simple, powerful, and future-ready.

Book a Demo Today

Ready to modernize your manufacturing facility’s visitor management?

Book a demo with Vizitor today and see how our solution can keep your operations secure, compliant, and efficient.

Frequently Asked Questions (FAQ)

1. What is a Visitor Management System (VMS) for manufacturing facilities?

A Visitor Management System (VMS) is a digital solution that helps manufacturing facilities securely track, monitor, and manage visitors, contractors, and vendors. It replaces manual logbooks with smart, automated check-in processes to improve safety, compliance, and efficiency.

2. Why is visitor management important in manufacturing plants?

Visitor management is crucial in manufacturing plants because it ensures workplace safety, protects sensitive areas, maintains compliance with industry regulations, and prevents unauthorized access to production floors.

3. How does a Visitor Management System improve compliance in factories?

A VMS helps factories meet compliance standards like OSHA, ISO, and other industry safety regulations by maintaining accurate visitor logs, issuing safety instructions, and ensuring audit-ready reporting.

4. Can a VMS integrate with existing security systems in manufacturing facilities?

Yes. Modern Visitor Management Systems, like Vizitor, integrate with access control systems, CCTV, employee attendance software, and emergency alert systems to create a unified security framework.

5. How does Vizitor support manufacturing facilities specifically?

Vizitor offers a cloud-based visitor management system designed to handle large-scale manufacturing environments. It provides touchless check-ins, contractor management, visitor badges, real-time monitoring, and compliance-ready visitor logs.

6. Is a Visitor Management System cost-effective for manufacturing plants?

Yes. By reducing manual work, preventing security breaches, and improving compliance, a VMS saves costs in the long run. It also boosts productivity by streamlining visitor workflows and minimizing downtime.

Latest Blog

How to Replace Manual Visitor Logs Without Disrupting Front Desk Operations

Fri, Feb 6, 2026

Replace manual visitor logs with a digital visitor management system without disrupting front desk operations. Learn a step-by-step approach to improve security, compliance, and visitor experience seamlessly.

Know more